Seiler Planetarium is part of the Seiler Instrument and Manufacturing Company. With offices throughout the Midwest, we operate out of our headquarters in Saint Louis, Missouri. Seiler has continued its tradition of expertise in precision optical instrumentation for over 75 years. We leverage our expertise in capabilities across all areas of focus, such as Manufacturing, Geospatial, Medical, and Design Solutions to provide services and support to our clients.

At Seiler Instrument Planetarium Division, it’s our job to know every inch of your planetarium. It’s a formidable task to survey just one planetarium; we have to be mindful of all the technical possibilities. It requires measuring EVERYTHING… usually, at least twice. Domed theaters are unique, and no two domes are alike. They range in size from 3m to 23m, can be tilted or flat, full or truncated, with perforated or solid screens. Pits, coves, knee walls, tilted floors, curved and/or spiral staircases are the norm. The nooks and crannies that result from putting a hemisphere in a square space can be strange, unpredictable, and very difficult and time-consuming to capture.

For my last “old school” site survey of a dome, I took over well 80 pictures and 50 measurements, and used a tripod, level, tape measure, laser distance meter, a gunner’s quadrant, a lot of trigonometry, and more than a little guess-work. It took about two hours of climbing over coves and crawling under seats to get a spreadsheet of data that was far from comprehensive. Interpreting the data also proved difficult; few people outside the industry know what a knee wall is.

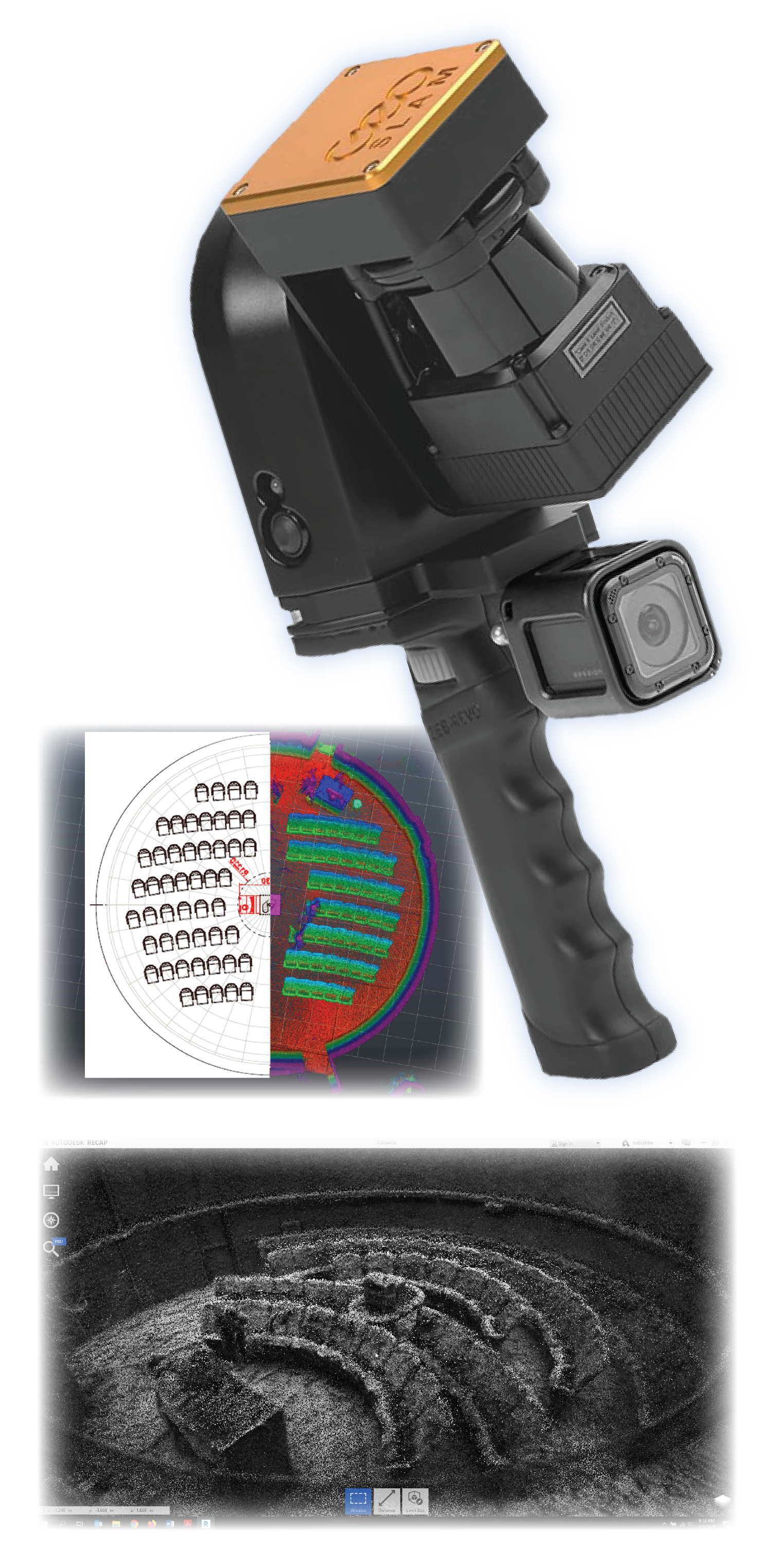

We needed a better way, and found the solution quite literally around the corner. Seiler’s Geospatial division provided us with a state-of-the-art GeoSLAM Zeb-REVO laser scanner and expert training from industry professionals. The improvement in our surveying process and results has been incredible.

Using the Zeb-REVO, I am able to produce a three-dimensional model of any area in just a few minutes. Gathering data is as easy as surveying the site with the naked eye, and the measurements are far more precise. The scanner easily captures compound curves, unreachable apexes, and imperceptible tilts. In terms of speed and accuracy, there is no comparison.

Now, scanning a planetarium typically takes ten minutes. Another ten is dedicated to peripheral areas like the lobby, offices, nooks and crannies, and path to the loading dock (areas often skipped back in the tape measure days). Back at the hotel, I process the data using the GeoSLAM Hub and import it to AutoDesk ReCap where the computer does all the work. The entire process takes less than thirty minutes, twenty to scan the theater and maybe five to upload the data. I never have to revisit a site or call and ask how high the seat pans are or how deep a wall is. The data can be directly exported to a .pdf or .cad drawing, which makes it easier on everyone. Finally, the planetarium receives the data for their own use; they can open Re-Cap and measure the diameter of the dome 10’ from the apex in a minute or two.

In time, laser scanners and 3D modeling will be the standard for site surveying. Right now, Seiler Instrument is drawing on its geospatial resources and expertise to set the standard.